Automation, flexibility and productivity are the main drivers we followed in the development of our new solutions.

Please join us at IFFA at our booth in the new Hall 12; we will be glad to show you our new technology to fast forward your productivity.

Thanks to know-how, build up in over 40 years of experience on different products and applications, we are capable of providing our customers with solutions based on an in-depth analysis of their specific needs. The perfect solution from our point of view is a mix of research, technology and tailor-made advisory that only a specialist can supply.

Want to speed up your business and achieve maximum performance? Join us at Stand A20 – A21, Hall 12, and let us show you how.

We will guide you to the best technology suitable to your needs, in order to get the best mix of productivity, yield and efficiency.

What you’ll find at our stand:

Discover our latest development and get one step closer to maximized productivity.

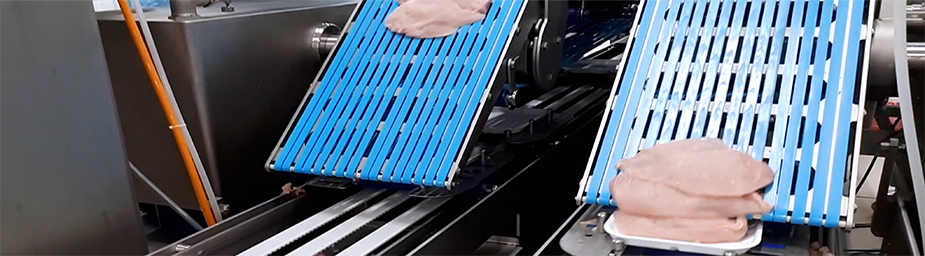

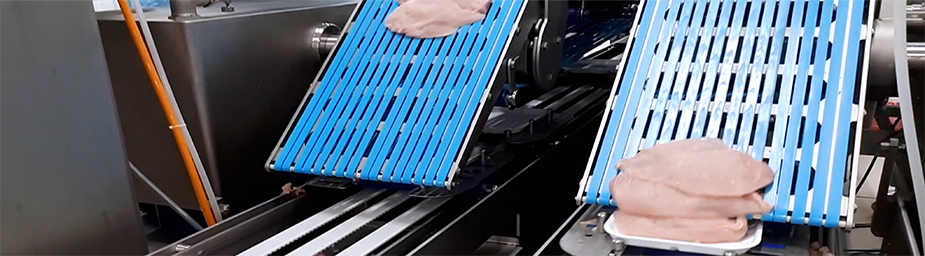

ATF LINE – Automatic Tray Feeding Line

The ultimate solution for automating the slicing and packaging process. Through a flexible modular approach, the line can be composed according to any specific need. Comprised of a slicing station, an automatic 3S Shingling Device and an Automatic Tray Filling Station, the full ATF line will cut perfectly even slices according to the customer’s recipe and place the grouped slices into trays, thus significantly minimizing both labor costs and product handling.

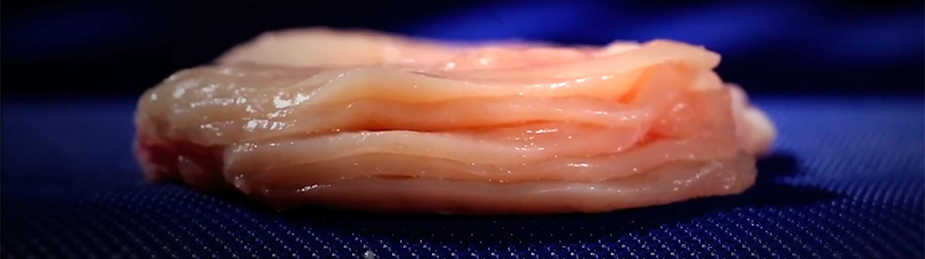

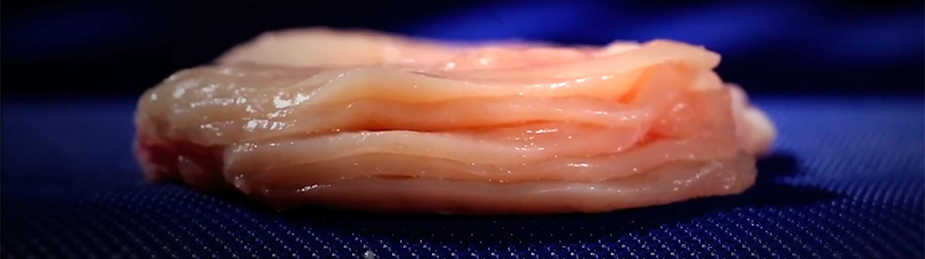

KSL DV – Horizontal slicer for NO WASTE slicing of fresh boneless chicken breast

Based on the product received on the in-feed belt and the recipe defined by the customer, the KSL DV automatically decides whether to slice the product, how many blades to use and the slicing thickness necessary to get maximum yield, maximum processing flexibility to get the highest productivity, and no waste, chicken breast after chicken breast.

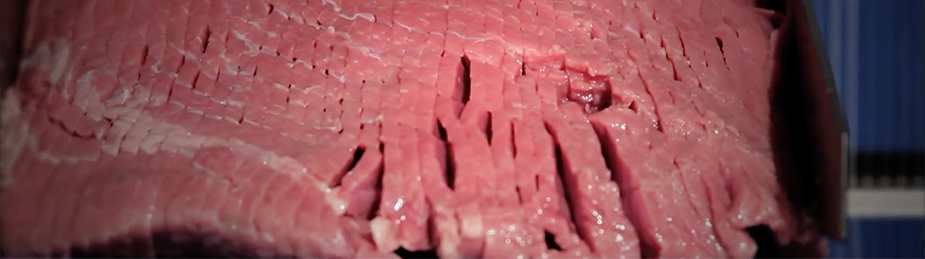

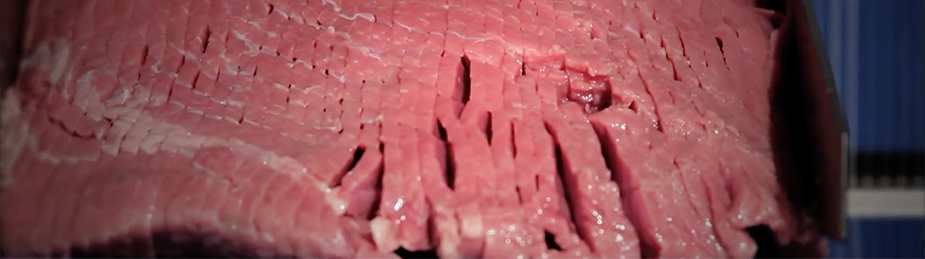

GBS – Band saw slicer for frozen and/or bone-in product

Able to slice frozen or bone-in product on pre-determined thickness, the new GBS results in high productivity with significant labor cost savings while maximizing safety and yield.

FSL600 YC – Vertical semi automatic slicer with yield control

Developed to guarantee maximum yield, FSL YC is equipped with an electronically controlled moveable wall inside of the slicing chamber that will enable to get virtually zero waste.

MS800 P DUAL BLADE

Ideal for large pork cuts, MS800 will be presented with the Dual Blade System, designed to remove and separate skin and fat in a single skinning operation, for major productivity and efficiency.

WLO – Wireless Safety system

WLO brings operator safety to the next level, thanks to a newly upgraded bluetooth connection and the complete removal of any wires on the operator. Test the true wireless safety.

When: May 4-9

Where: Frankfurt Am Main

Stand: Hall 12, Stand A20 – A21