Weight accuracy even with the most irregular product shapes.

The PAD + KSL DV Line is ideal when portions of an extreme precise weight are required.

Automatic and semi-automatic vertical and horizontal slicers.

The PAD + KSL DV Line is ideal when portions of an extreme precise weight are required.

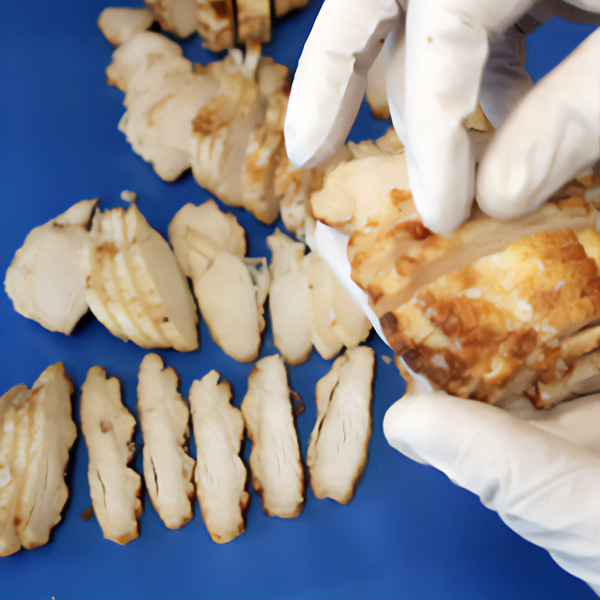

Designed to guarantee perfect tuna fillets for the filling of jars while minimizing the giveaway due to the cutting operations.

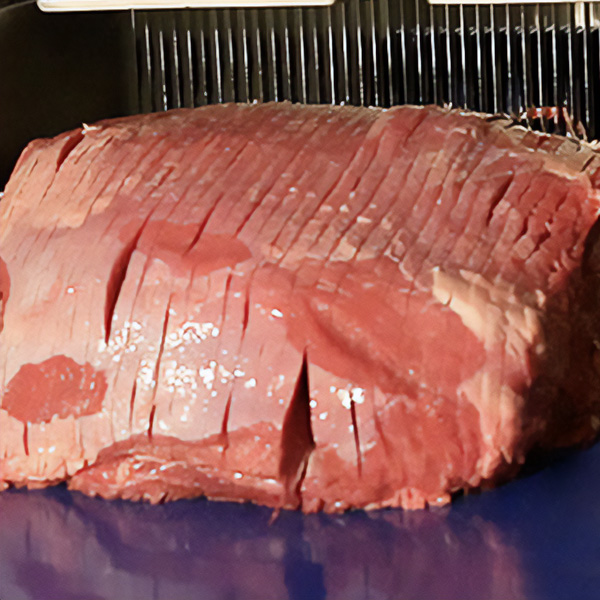

Extreme precision and quality even for thinner slices, in addition to high productivity and yields: the market standard for vertical slicing of fresh meat.

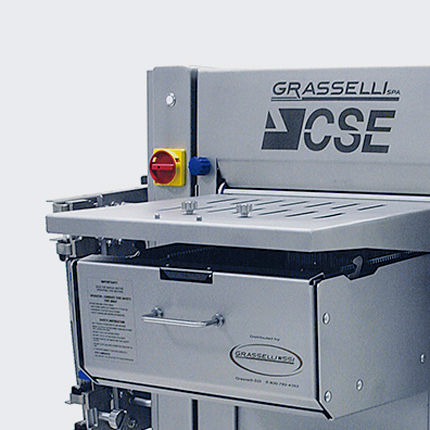

Extremely versatile solution for the processing of fresh meat, thanks to the external electrical system that makes it easier to access the components for cleaning.

Adjustable cutting parameters and highly efficient, “gentle” technology for the most delicate cuts.

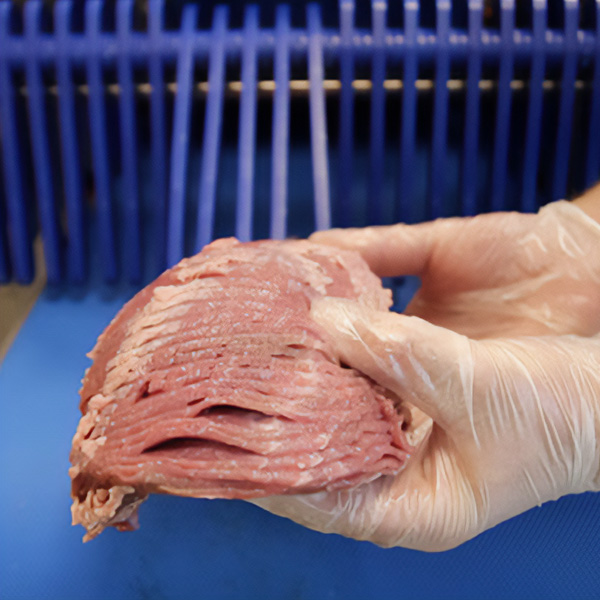

With a cutting capacity of up to 4000 kg/h, KSL CBU is a horizontal slicer for fresh meats with a slice splitting conveyor belt, ideal for poultry meat.

The KSL CBU 3B cuts products with unparalleled precision, automatically separates the slices into three groups and deviates them on three different outfeed belts. Maximum efficiency and extreme flexibility.

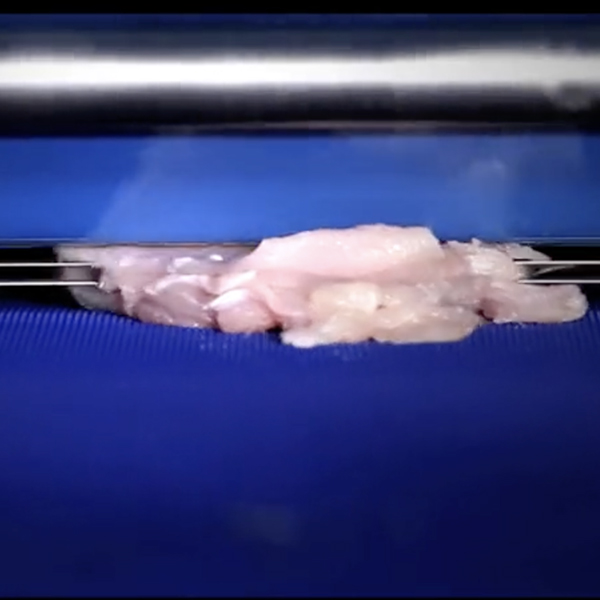

For each chicken breast, according to the recipe settings, the KSL DV automatically decides whether to slice the product, how many blades to use and the ideal slicing thickness.

Fully automatic product infeed and outfeed: an ideal in-line solution for obtaining perfectly even slices also with thinner settings.

Slicer for 2D cutting, able to produce strips or cubes with even or slightly irregular dimensions (for a “hand-cut” effect).

Extreme cutting precision and high productivity, for 2D cuts in strips or cubes, as part of a fully in-line process with an extremely high yield.

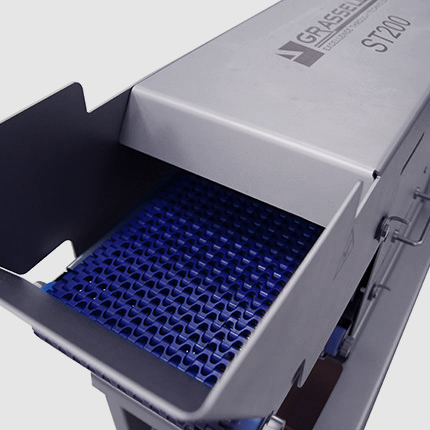

Completely sanitizable on both the outside and inside.

The ideal solution for anyone who wishes for a reliable, versatile, easy to sanitize machine with reduced dimensions. Perfect for restaurants, catering companies and butchers.

Compact vertical slicer for fresh boneless meats, extremely versatile, easy to install in any work environment.